-

Automatic Filling Device - Piston

- Application: Beverage, Yogurt, Detergent, Oil, Shampoo, Body lotion, Sauce, Jam, Honey…etc. other liquid product.

- Accuracy: +/- 1~3%.

- Filling Rang: 25~1,200ml.

- Can be connect with CIP system.

- Transmission system is driven by cylinder or servomotor.

-

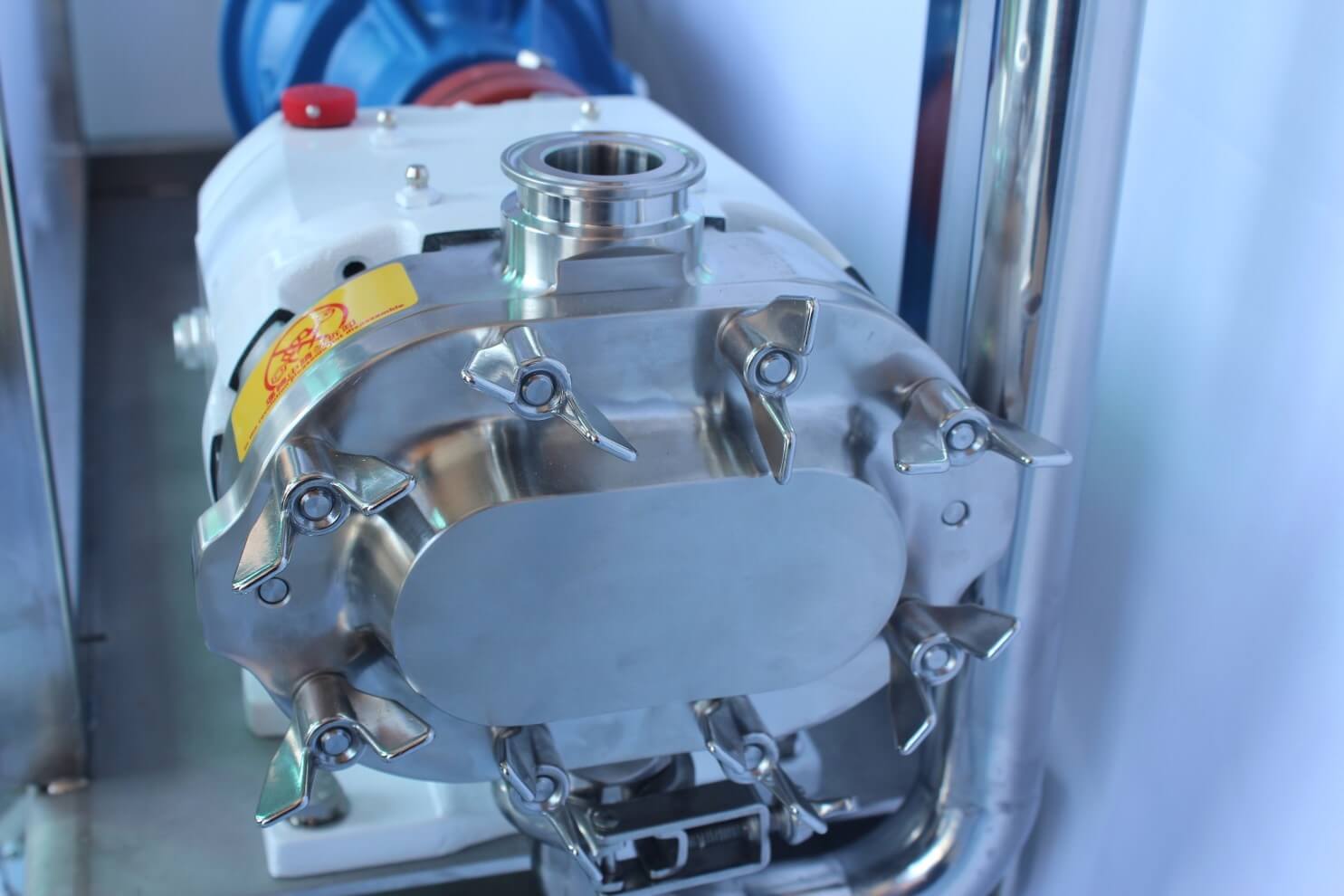

Rotary Lobe Pump Filler

- Application range: containing particles, high viscosity (concentrated liquid), high pressure fluid transportation, quantitative filling, etc.

- Accuracy: +/- 1~3%.

- Filling Rang: 250~2,000ml.

- Easy to clean and can be online CIP.

-

Auger Filler

- Application : Powder, granule, crude sugar, salt, flour, coffee powder, monosodium glutamate, seasoning flavor, chemical powder, biological powder …etc.

- Accuracy : +/- 1~3%.

- Filling Rang : 0.1~2,000g.

- The transmission system is driven by servo motor.

- Easy to install and dismantle the auger without any tool.

- Easy and convenient cleaning for time-saving.

-

Multi-Head Weigher Filler

- Application : Nut, beans, candy, cereal, frozen chuck meat, frozen dumpling, fruit, shredded cheese, chocolate ball, Coffee Bean…etc.

- Accuracy : +/- 1 %.

- Filling Rang : 10~2,000g.

- All Contact Parts Are Completely Tool-Less : Pans, buckets, chutes and the hopper are all designed for quick and easy removal.

- Electronics are centrally and conveniently located in a remote mounted electrical enclosure at floor level, safety of electronics is assured during wash-down and from machine vibration.Individual product slide chutes for increased speeds with no spiraling.